About Cryo Technologies

Expertise

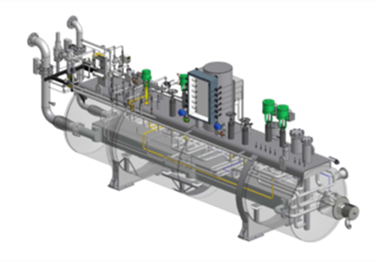

Cryo Technologies' staff is comprised of highly skilled and experienced engineers and designers who are career-long experts in deep cryogenic system design. Our full range of engineering and design competencies include process, mechanical, instrumentation, controls, safety, procurement, quality assurance, project management and 3D modeling.Chart acquired Cryo Technologies in 2021 with the two companies having previously worked together for more than 20 years. “We could not be more excited to welcome Rick and the Cryo Technologies team into the Chart family. Their world class, differentiated cryogenic engineering expertise, global project experience in hydrogen and helium liquefaction coupled with our process technologies, brazed aluminum heat exchanger and cold box manufacturing capabilities creates the only multi-molecule full-solution liquefaction and equipment offering in the world.” Jill Evanko, Chart CEO and President.

“Our people possess extensive education, knowledge and experience in all engineering and design disciplines including process, mechanical, instrumentation and controls, safety, quality assurance and project management.” Rick Hessinger, Cryo Technologies President.

Applications

- Hydrogen Liquefaction

- Helium Liquefaction

- Natural Gas Liquefaction (LNG)

- Cryogenic Purification - Helium and Hydrogen

- Helium Recycling

- Nitrogen Liquefaction and Re-Liquefaction

- Oil Removal

- Tritium Removal

- Vacuum Insulated Pipe and Distribution

- Warm Gas Purification

- Cold Gas Compression

- Monomer Recovery

}

Cooler Together

Chart acquisitions Cryo Technologies and Fronti Fabrications have been working together for more than 30 years utilizing their deep cryogenic expertise to create solutions for purifying and liquefying hydrogen and helium. Together with our brazed aluminum heat exchangers, cold boxes and cryogenic storage tanks, Chart has the unique advantage of being able to fully design engineer, build and assemble complete plants in house.

Video Section

Contact Cryo Technologies

Global supplier of custom cryogenic and non-cryogenic processing systems and equipment.Cryo Technologies Main Office +1 610 530 7288

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team